The building envelope of your Hanse Haus: make your own personal contribution to the energy transition

There are many ways to build a house. At Hanse Haus, the decision in favour of prefabricated timber houses was made a long time ago, when the small carpentry business Hanse Fertighaus Bau was founded in the Hanseatic city of Lübeck in 1929. Since then, we have continuously developed our construction technology, utilised our experience and continually improved the wall structure in timber panel construction. Build your energy-efficient, sustainable home with us.

Classic craftsmanship meets high-tech at Hanse Haus

Building on quality.

A team that knows its trade

We believe that machines can never replace years of accumulated expertise and genuine craftsmanship – they can only complement it. For this reason, we still employ real professionals who have learnt their trade from the ground up.

From planning to prefabrication and assembly to interior finishing, we can cover every trade with our own employees. And to ensure that this remains the case in the future, we train our own junior staff.

Tested quality offers security

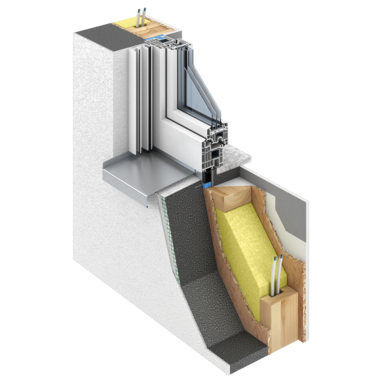

As part of the quality control process, our external walls, including windows and doors, are subjected to climate chamber tests: they are exposed to strongly fluctuating temperatures and rain simulations over several weeks. This means you can be sure that the components fulfil all climatic requirements.

We also rely on tried and tested methods for our production site: all Hanse houses are prefabricated in our factory in Oberleichtersbach in Lower Franconia.

Hanse Haus wall construction: A KfW 40 Plus building envelope as standard

Save energy with all-round thermal insulation

We hear and read everywhere that we should use more alternative energy sources and rely on energy-saving, efficient heating technology. That's the way in which we think.

At Hanse Haus, we start even a step earlier and ensure that you get by with as little energy as possible in your prefabricated house. This not only saves running costs, but also protects resources and the environment.

The thicker the thermal insulation of a house, the better the heat is kept inside. This means that less energy is used for reheating.

In order to minimise heat loss through the building envelope, we rely on all-round thermal insulation that covers all exterior walls, the roof, windows and doors as well as the cellar or floor slab if necessary. The interior walls are also insulated as standard.

Timber panel construction

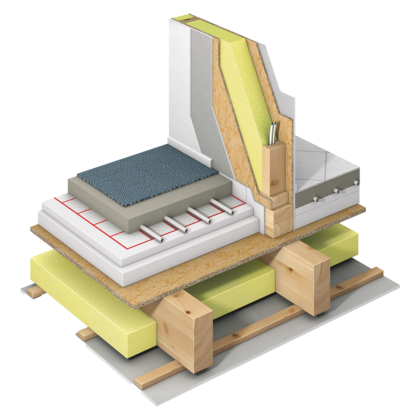

Our external wall construction for the Hanse Haus prefabricated house

Our ThermoEfficiency wall combines a high-strength construction method with outstanding thermal insulation. The timber frame is hot-glued with high-quality OSB panels under pressure. This creates the panels of the so-called timber panel construction with timber frame construction.

Your advantage: you can attach shelves or cupboards weighing over 250 kg anywhere, on any wall, in any room using normal screws. No drilling or dowelling required.

The clear room height (finished height) in ground floors, upper floors and attics is approx. 2.50 metres, measured from the upper edge of the finished floor to the lower edge of the finished ceiling. Greater room heights, e.g. 2.70 metres, are possible ex works on request.

Advantages of wall construction

Advantages of the Hanse Haus wall construction

- Our walls are suitable for the construction of KfW Efficiency Houses 40 Plus as standard.

- The U-value in the compartment area is only 0.116 W/m²K (total wall only 0.131 W/m²K).

- We use high-quality solid structural timber, planed and kiln-dried for natural wood protection.

- The reinforcement plaster applied in the factory protects against the effects of the weather - even during assembly.

- The seamless external render, which is only applied on site after the house has been assembled, ensures a high-quality external appearance of the house.

- We are happy to offer you alternative façade designs such as clinker brickwork or timber cladding on request.

Experience quality live

Wall quality you can touch

Can't imagine what the figures and values mean and find the technical specifications difficult to grasp?

Visit one of our show houses in your area and convince yourself of the characteristics and advantages of the timber panel construction method successfully used by Hanse Haus.

Our local advisory teams will be happy to answer your questions and provide non-binding advice. They will also provide you with detailed information about additional sound insulation with Knauf solid building boards or diamond hard gypsum boards, high-quality external thermal insulation composite systems and acoustic panels from Sto as well as the best Braas insulation.

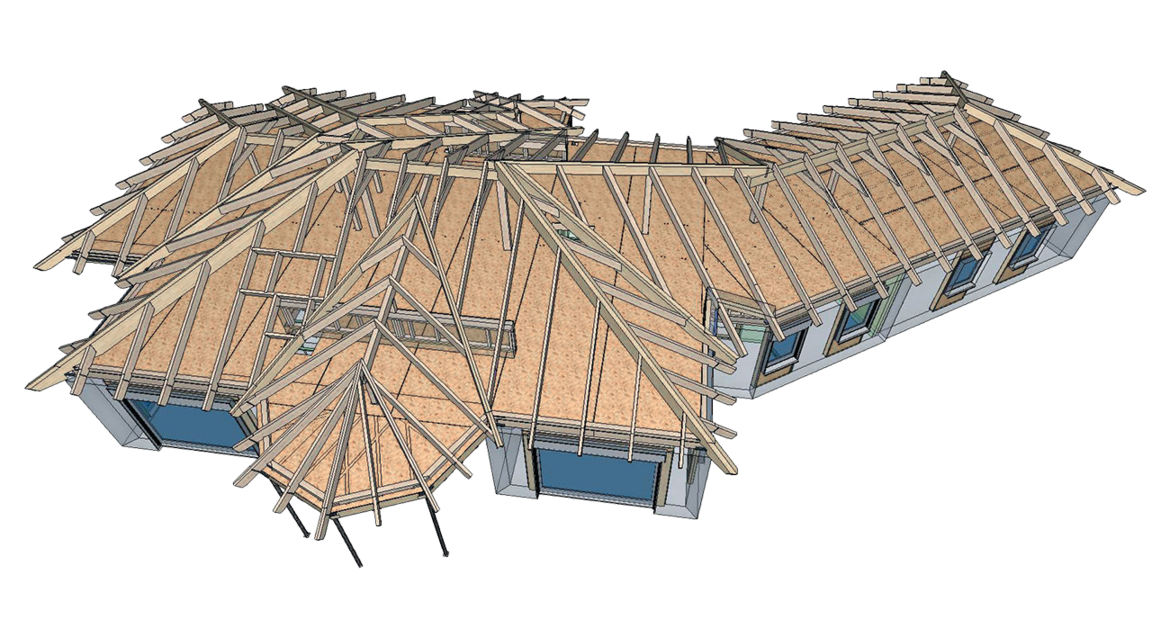

The roof structure at Hanse Haus

Solid timber construction and optimum thermal insulation

No other factor in a house has such a decisive influence on low energy consumption as the building envelope.

In addition to the excellent insulating properties of the walls, the roof structure of Hanse Haus also ensures perfect thermal insulation.

It not only keeps the heat inside the house in winter, but also protects against heat in summer. Even the standard thermal insulation of our roof structure fulfils the requirements for a KfW Efficiency House 40 eligible for subsidies.

High-quality construction

Solid timber construction for the roof structure

All roof trusses from Hanse Haus are built by carpenters using solid timber construction. In our production, we use state-of-the-art equipment and qualified carpenters who ensure maximum accuracy of fit and quality.

Our roof trusses are made from solid kiln-dried softwood in planed solid structural timber quality and, depending on the structural requirements, in parts from glulam elements. Visible rectangular supports and beams on the outside (e.g. for canopies or carports) are made of high-quality glulam. On the outside, all visible components are given a protective coat of paint.

A tour through our factory in Oberleichtersbach in Lower Franconia will give you an insight into our production process.

Advantages of the roof structure

Advantages of the Hanse Haus roof structure

- You can rely on the carpentry construction of your roof truss made of quality-tested, sustainably produced solid timber and glulam.

- Your roof is designed as standard for a snow load of up to 1.5 kN/m² – depending on regional requirements.

- You receive a 30-year manufacturer's guarantee on the functionality of our concrete roof tiles.

More info

We answer your questions about roof construction

Are you interested in the details of roof construction? For example, how a pitched roof compares to a hipped roof, mono-pitch roof or flat roof? Or which insulation we use in our prefabricated house roof structure?

Please feel free to contact us. Our highly trained specialist advisors will tell you everything you need to know about the construction technology used. You will also find detailed information in our current construction services and equipment description, which we will be happy to send you.

More about the Hanse Haus building envelope

The floor and ceiling construction at Hanse Haus

Quality from floor to ceiling

We also use high-quality building materials for our floor and ceiling constructions, such as heavy-duty wood-based panels and a beam layer made of kiln-dried solid structural timber.

This ensures that the required fire resistance classes, sound insulation values and impact sound levels are achieved.

You can find out everything you need to know about the floor and ceiling construction in our prefabricated houses from our Hanse Haus consulting teams in your area.

You will also find detailed information and sketches of our building technology in our current building performance and equipment description, which we will be happy to send you.

Request information material

Request without obligation & free of charge our prefabricated house catalog with detailed information about the company as well as all house designs or construction performance and equipment descriptions. In addition, you will find the prices for our campaign houses in our campaign brochure.